In the cost structure of construction projects, door and window procurement occupies a proportion that cannot be ignored.

For customers, a successful door and window procurement not only affects the quality and delivery cycle of the project, but also directly affects the overall cost control. However, the door and window procurement market is mixed, and various traps are hidden in it. If you are not careful, you may fall into the dilemma of cost waste.

The following is a summary of common traps in door and window procurement by customers, and provides practical pit avoidance methods.

1. Low price trap: Beware of the appearance of "good quality and low price"

Some suppliers attract customers with quotations far below the market average price. These low-priced products often have serious quality risks. For example, the use of recycled aluminum profiles to make aluminum alloy doors and windows has a strength and corrosion resistance far inferior to that of original aluminum, and is prone to deformation and breakage during use; glass thickness does not meet the standard, the sealing strip is of poor quality, etc., which will greatly reduce the heat insulation, sound insulation and waterproof performance of doors and windows. The subsequent maintenance and replacement costs will far exceed the initial savings in procurement costs.

Avoidance method: Before purchasing, fully investigate the market price and understand the reasonable price range of doors and windows with different materials and processes. Require suppliers to provide raw material test reports, product quality certification and other documents, conduct on-site inspections of manufacturers, check production equipment, processes and quality control processes, and avoid greater losses due to greed for low prices.

2. Contract terms trap: vague statements hide risks

Some bad suppliers tamper with the contract terms and set traps through vague quality standards, delivery time and after-sales terms. For example, the contract does not clearly describe the key parameters of the profile thickness and glass specifications of doors and windows, and inferior products are used as good ones during acceptance; the delivery time is not clearly agreed, resulting in project delays; the responsibility of after-sales terms is vague, and there is a shirking of responsibility when problems arise.

Avoidance method: Before signing a contract, be sure to carefully review each clause to ensure that the quality standards are clear and specific, cite international or national standards, and indicate the brand, model, and specification parameters of profiles, glass, hardware, etc. Clearly stipulate the delivery time, location and liability for breach of contract, including compensation for overdue delivery. Refine the after-sales terms, stipulate the warranty period, maintenance response time and cost-bearing method, and consult professional legal advisors when necessary.

3. Supplier qualification trap: false propaganda confuses choice

Some suppliers exaggerate their own strength and falsely advertise production scale, technical level and successful cases. They promise to provide personalized customization solutions without a professional design team, and accept excessive orders without large-scale production capacity, which ultimately leads to products that cannot meet project requirements or delayed delivery.

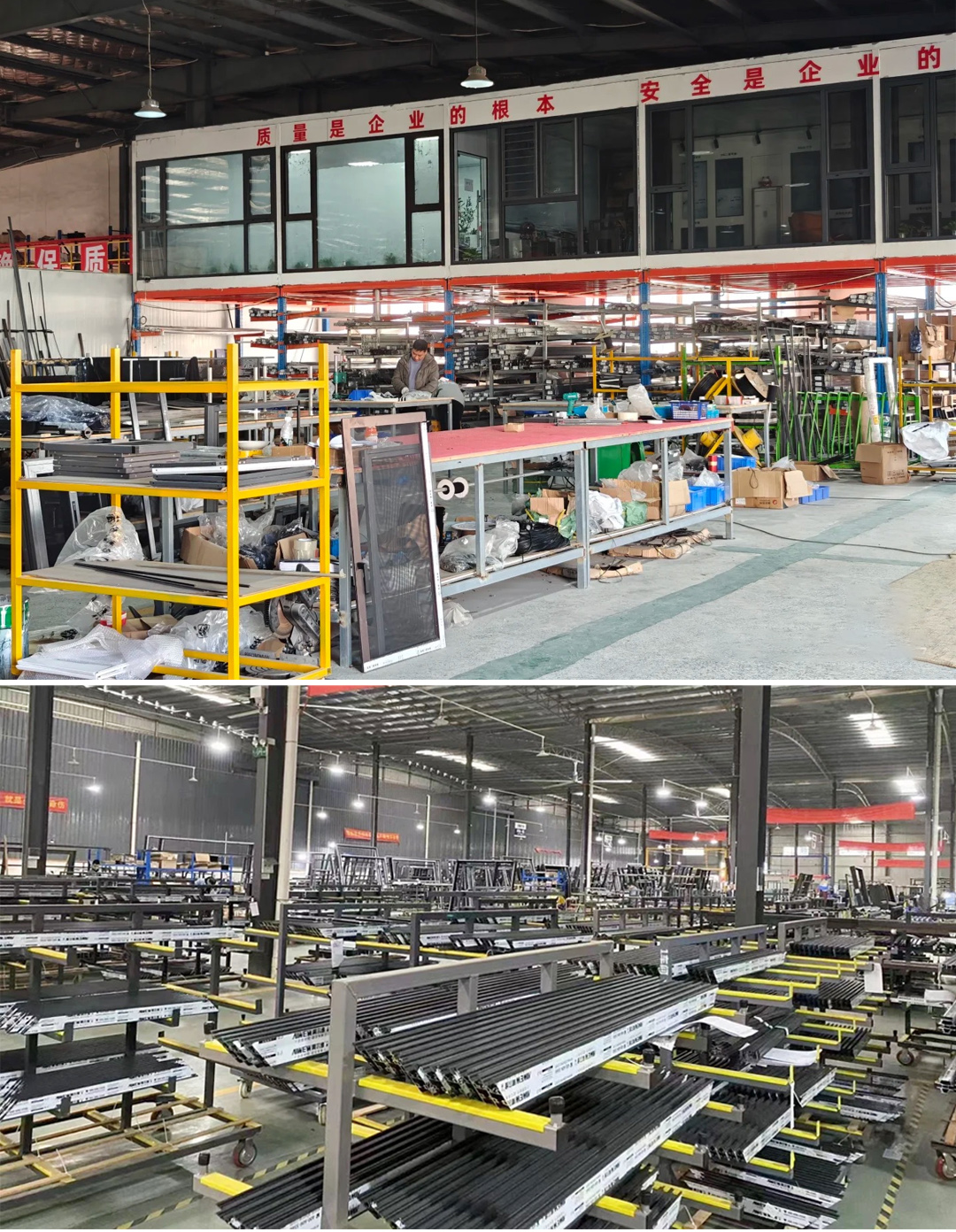

Avoidance method: Verify the qualifications and reputation of suppliers through channels such as the corporate credit information disclosure system and industry associations. Require suppliers to provide detailed information on past cooperation cases, including project names, contact information, etc., for field visits or telephone follow-up. Give priority to suppliers with industry reputation and long-term stable operations.

4.Transportation and installation trap: additional costs increase costs

During the transportation process, there may be suppliers who deliberately raise freight rates or make a fuss about transportation insurance, and refuse to take responsibility if the product is damaged. The installation process also hides risks. For example, if the installation team is unprofessional, the doors and windows will not be installed in a standardized manner, and problems such as poor sealing and poor switching will occur. Later rectification will require additional fees.

Avoidance methods: specify the mode of transportation, freight bearer and insurance liability in the contract. You can ask the supplier to provide a detailed transportation quotation and compare it with the market price. For installation services, require the supplier to provide the qualification certificate of the installation team, personnel training records, etc., stipulate the installation quality standards and acceptance methods in the contract, and pay the installation fee after the acceptance is qualified.

To eliminate cost waste from the source in the purchase of doors and windows, you need to be vigilant in all aspects of the purchase, identify potential traps, and use scientific and reasonable avoidance methods. Choose reliable suppliers, sign rigorous contracts, and strictly control the transportation and installation links to ensure that the purchased doors and windows are of high quality and low price, providing a solid guarantee for the smooth progress of the project.