In real projects, color consistency is rarely discussed at the design stage. It becomes an issue only when components are installed and viewed together in their final position. This is especially true for patio sliding door systems, which are often repeated across multiple units or façades.

Once installed, these doors are exposed to strong daylight, wide viewing angles, and continuous visual comparison. What looks acceptable on a single sample can appear inconsistent when dozens of frames line up across a building. At that point, color deviation stops being a minor detail and turns into a visible project risk.

For developers and contractors, such issues usually surface during inspection and handover. Questions are no longer limited to appearance, but extend to whether the system can deliver consistent results across phases, batches, and installation schedules. In a large real estate development project, visual inconsistency is rarely treated as an isolated defect—it is often interpreted as a signal of broader system control risks.

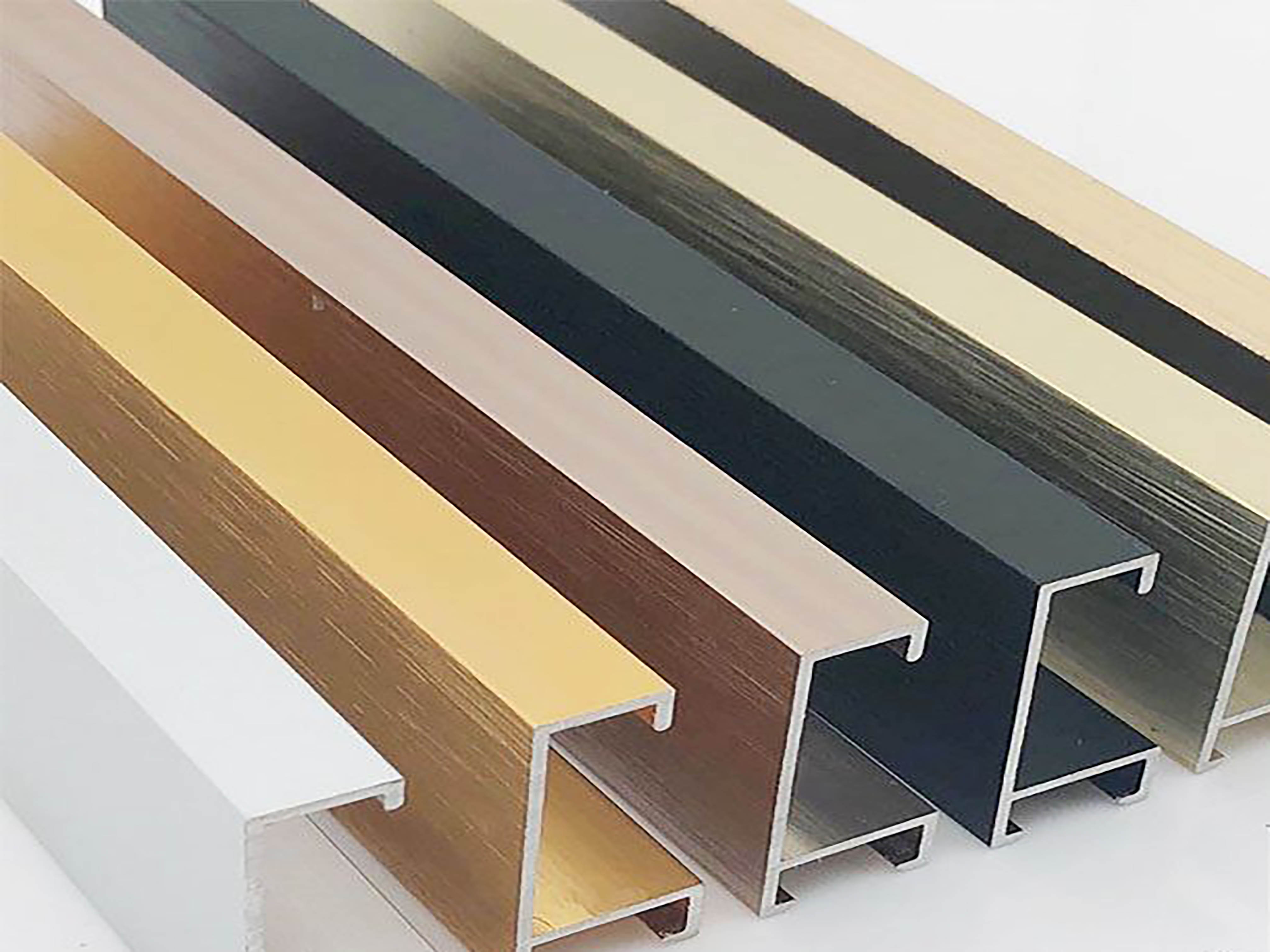

Common Causes of Color Variation in Aluminum Door Frames

Most color variation problems do not come from one obvious mistake. They are typically the result of several small deviations accumulating along the production chain. In practice, color variation often becomes visible at the aluminum sliding door frame, where extrusion quality, surface preparation, and finishing conditions intersect most directly.

Differences in raw aluminum billets can affect how the aluminum profile color responds to surface treatment. During extrusion, variations in temperature or pressure influence surface density, which later changes how coatings or anodized layers appear under light.

Surface preparation is another frequent source of inconsistency. Changes in profiled surface roughness alter reflection and gloss, creating visible differences even when the same finish is applied. When long profiles are coated unevenly or processed across different finishing lines, variation becomes even harder to control.

Surface Treatment Processes and Color Stability

Surface treatment is where color stability is either secured or lost. In powder coating, consistency depends on controlled application, stable curing conditions, and uniform film thickness. Small fluctuations may not be obvious immediately, but they become visible once profiles are assembled and compared.

For anodized finishes, the process is even more sensitive. Color formation depends on controlled oxide growth and dye absorption. Without strict anodizing process control, profiles produced in different batches may show noticeable tone differences, especially under outdoor lighting.

Pretreatment quality is often underestimated. Inadequate cleaning or chemical imbalance affects adhesion and visual uniformity, reducing long-term reliability.

Production-Level Color Control Methods

Effective color control is rarely achieved through final inspection alone. It starts with disciplined production planning. Separating material batches, using approved reference samples, and maintaining traceability across extrusion and finishing stages help reduce unexpected variation.

Visual inspection should be carried out under standardized lighting conditions. This reduces subjective judgment and allows different operators to make consistent decisions throughout the production cycle.

Color Matching for Large Patio Sliding Door Systems

The challenge increases significantly with large sliding patio doors and multi panel sliding door configurations. A system may include frames, sashes, tracks, and cover profiles produced at different times.

Vertical and horizontal elements reflect light differently, which can exaggerate perceived color differences. Corner joints and connectors are particularly sensitive, as even small mismatches become noticeable at intersections. Coordinating multiple production lines requires shared color references and synchronized process control.

Testing and Quality Verification Before Delivery

Before shipment, color verification should combine visual evaluation with objective measurement. Color measurement instruments help define acceptable tolerance ranges, while mock-up assemblies reveal how components appear once installed together.

Proper packaging is also part of quality control. Surface damage during transport can compromise appearance and undermine otherwise stable production results.

How Color Consistency Impacts Project Approval and Brand Trust

On site, color consistency is judged instantly. Visible mismatch can delay approval, increase rework, and disrupt schedules. Over time, concerns about fading and exposure affect confidence in architectural aluminum profiles.

From a project owner’s perspective, consistent appearance reflects a manufacturer’s ability to manage complexity and deliver predictable outcomes, not just individual components.

Conclusion: From Process Control to Project Confidence

Color consistency is not achieved by one process or one inspection step. It is the result of coordinated material control, stable surface treatment, disciplined production, and realistic verification.

In patio sliding door projects, especially those involving large openings and repeated installations, consistent color performance becomes part of overall system credibility. When managed well, it supports smooth project delivery and long-term trust.