In aluminum casement window systems, talking about failure modes shows engineering discipline. It does not mean the quality is poor. Every window system is the result of multiple technical decisions, and understanding potential failure paths is a core part of risk identification in architectural products.

As casement windows are widely used in residential, commercial, and renovation projects, including casement replacement windows, their long-term performance directly affects building comfort, durability, and energy efficiency. Failure modes often emerge gradually, driven by the interaction between climate exposure, structural load, and material behavior. Identifying these risks early allows system designers and manufacturers to control performance outcomes more effectively.

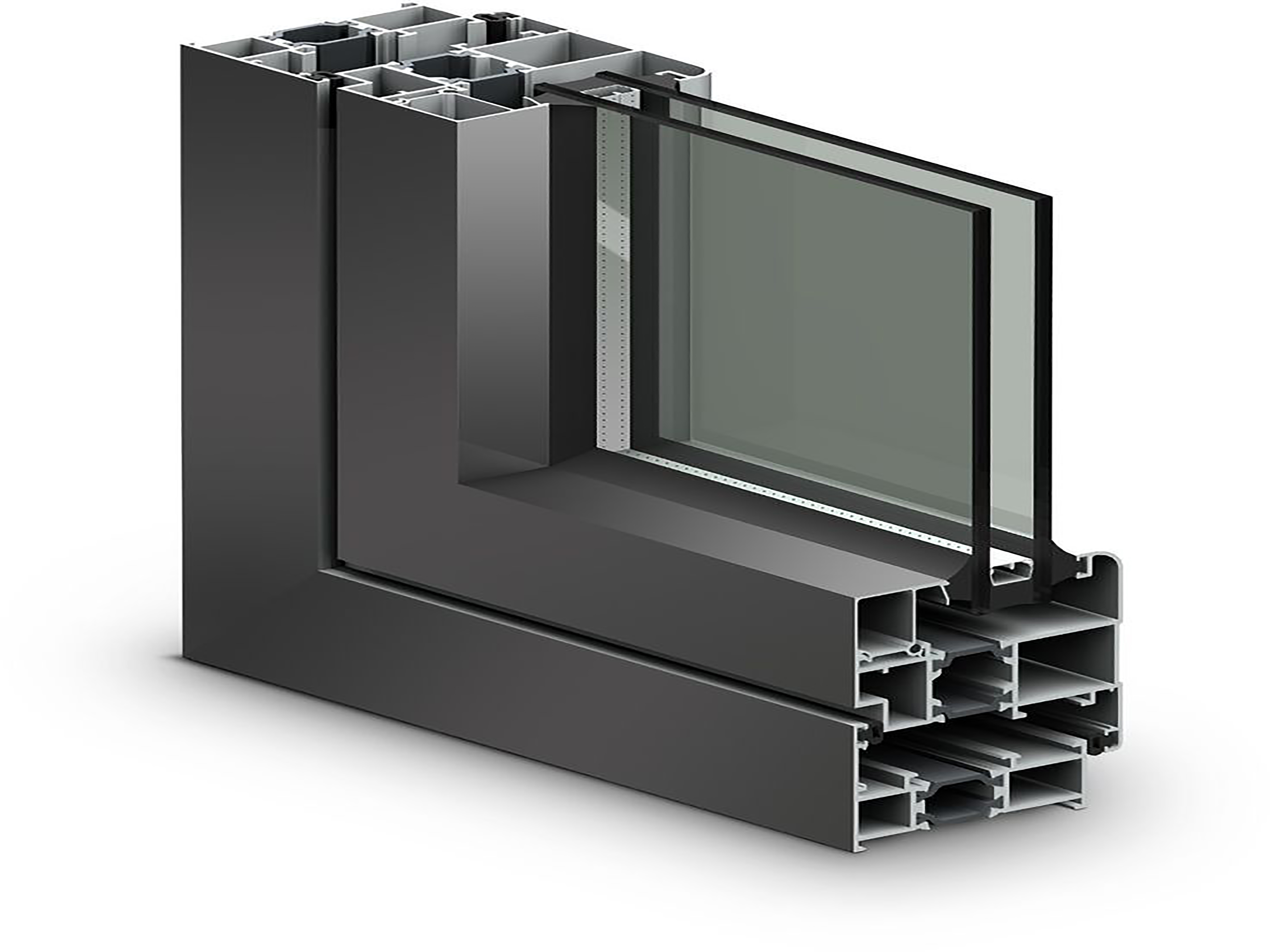

Classification of Failure Modes in Casement Window Systems

A systematic classification helps clarify where and why failures occur. In aluminum casement window systems, most failure modes can be grouped into design-related, manufacturing-related, testing-related, and installation-related issues.

Design-Related Failure Modes

Design-related failures often originate from incorrect assumptions. One common issue is profile geometry mismatch, especially when standard profiles are applied to large openings without recalculating structural capacity. This can lead to excessive deflection under wind pressure.

Another frequent design challenge involves thermal break configuration. If thermal breaks are not optimized to adapt to climate conditions, localized thermal bridging may occur. This increases heat transfer and raises the likelihood of condensation, making early-stage condensation risk analysis essential for system reliability.

Manufacturing-Related Failure Modes

Manufacturing accuracy has a direct impact on system performance. Dimensional deviations in aluminum profiles can affect sash movement and sealing consistency. Inconsistent surface treatment may reduce gasket contact quality, while variation in corner joint processes can weaken structural continuity.

These issues are particularly critical for suppliers serving multiple markets, including aluminum storm window manufacturers, where consistency across batches is necessary to maintain predictable performance.

Testing-Related Failure Modes

Testing-related failures are often hidden until after installation. Insufficient water penetration testing may overlook leakage paths that only appear under combined wind and rain exposure. Similarly, limited long-term airtightness validation can fail to detect gradual seal degradation.

When testing samples do not represent real installation conditions, performance data may not align with actual building behavior, increasing the risk of post-installation issues.

Installation-Related Failure Modes

Installation quality plays a decisive role in system performance. Misalignment between frame and sash can increase air leakage, while improper sealing at interface zones allows moisture ingress. Blocked or altered drainage paths during installation further reduce the system’s ability to manage water under pressure.

Critical Parts Where Failures Commonly Occur

Frame–Sash Interface

The frame–sash interface is one of the most sensitive zones. Tolerance stacking can lead to air leakage, while uneven compression of sealing gaskets reduces both airtightness and durability over time.

Glazing and Edge Sealing Zones

Failures frequently occur at glazing interfaces, where discontinuous seals allow water infiltration. At the glass-to-frame junction, insufficient insulation detail may create thermal bridging, affecting overall thermal performance and increasing condensation risk.

Corner Joints and Drainage Systems

Corner joints are subjected to combined structural and environmental stress. Micro-leakage at these connections may develop gradually, while insufficient drainage capacity can lead to water accumulation under wind-driven rain conditions.

How Failure Modes Lead to Performance Degradation

When failure modes are not addressed, performance degradation becomes measurable. Increased air leakage reduces thermal efficiency, while moisture ingress compromises material stability. Over time, these issues may negatively influence compliance with NFRC window ratings, particularly in projects with strict energy performance requirements.

Role of Testing in Identifying and Preventing Failure Modes

Testing serves as a verification tool between design intent and real-world conditions. Comprehensive testing programs help identify weak points, validate assumptions, and refine system details before large-scale application. Proper testing supports performance consistency rather than reactive problem-solving.

How System-Oriented Design Reduces Failure Risks

System-oriented design considers profiles, hardware, glazing, sealing, and drainage as interdependent components. By evaluating the complete assembly rather than isolated parts, designers can reduce cumulative risk and improve overall reliability. This approach is especially valuable in complex projects involving diverse climate exposure.

Managing Failure Modes Through System Thinking

Through system thinking and disciplined engineering, stakeholders can reduce uncertainty, control long-term performance, and deliver window solutions that meet modern architectural and environmental expectations.